As part of the collaboration, we implemented our systems in 14 garbage trucks belonging to Fresh Start Waste.

This was a significant step towards optimising the processes involved in waste management. The implementation included a number of key components:

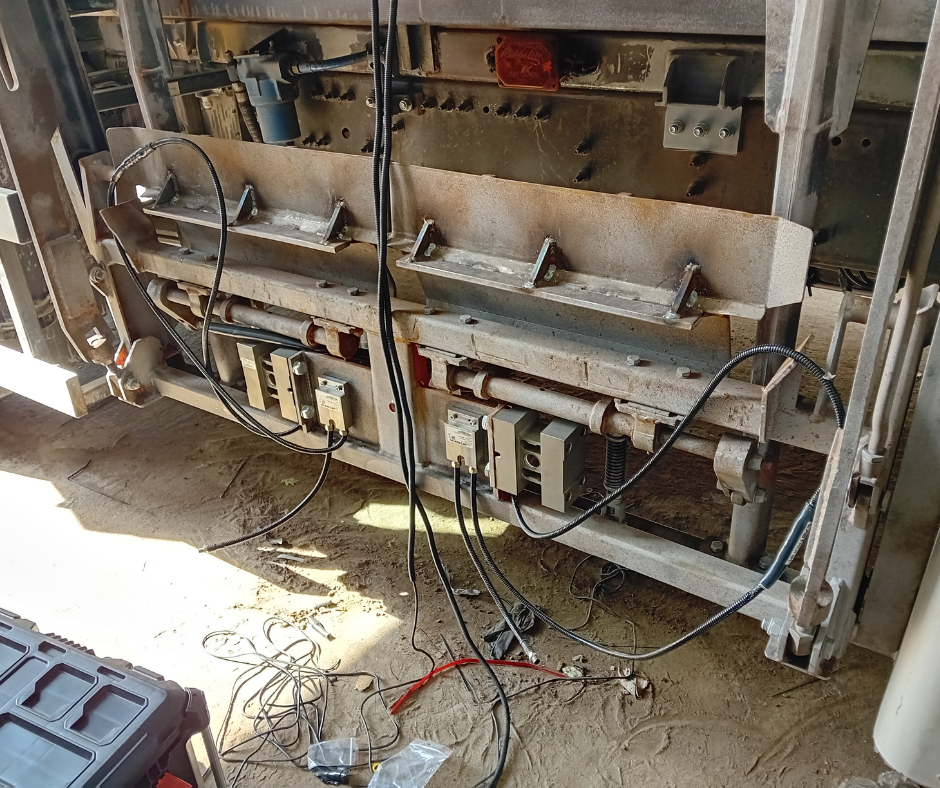

Automation and monitoring – each vehicle is equipped with dynamic weighing system, comprising: a scale, 4 load cells and ICHI software. This solution allows the weight of the waste to be read already at the moment of dropping in from the front and rear drop-in device, and the data is immediately transmitted to the database. The lifter does not have to be stopped by an employee (as with a static scale) to weigh the container, saving time.

Additionally, implemented RFID identification systems allow precise identification and monitoring of containers. This solution gives full control of the process and streamlines data management.

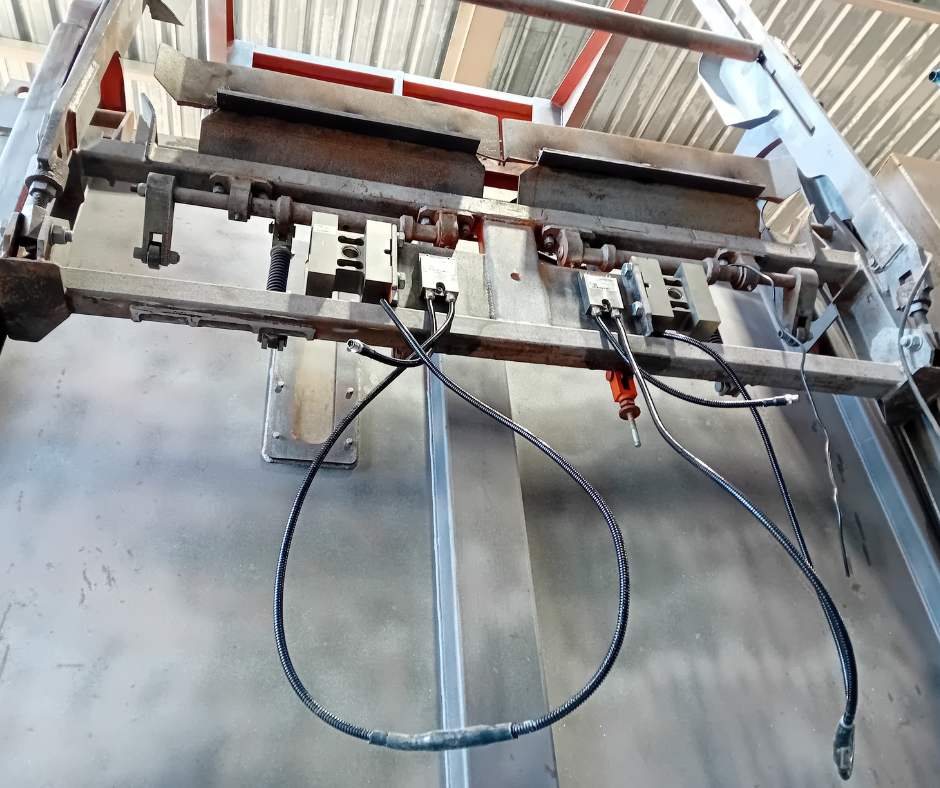

The vehicles were not factory-adapted for installation of the RFID system and dynamic weighing scale. It was necessary to adapt truck lifters to enable the installation of both systems.

Adaptation of the lifter to allow the installation of rfid system and dynamic weighing scales.

Our proprietary software, ICHI System, enables the generation of detailed reports and data analysis of waste collection and processing. ICHI also has an extensive planning module and route optimisation. With it, the dispatcher can send messages and tasks to installed terminals in rubbish trucks, and with just a few clicks, drivers report the status of the process.

This is another successful implementation at Fresh Start Waste. Smooth implementation and understanding on both sides will certainly result in many joint activities.